An efficient and sustainable approach to recyclable paper packaging: Koehler Paper and HDG-Verpackungsmaschinen present their newly developed “pressure seal module” and flexible packaging paper.

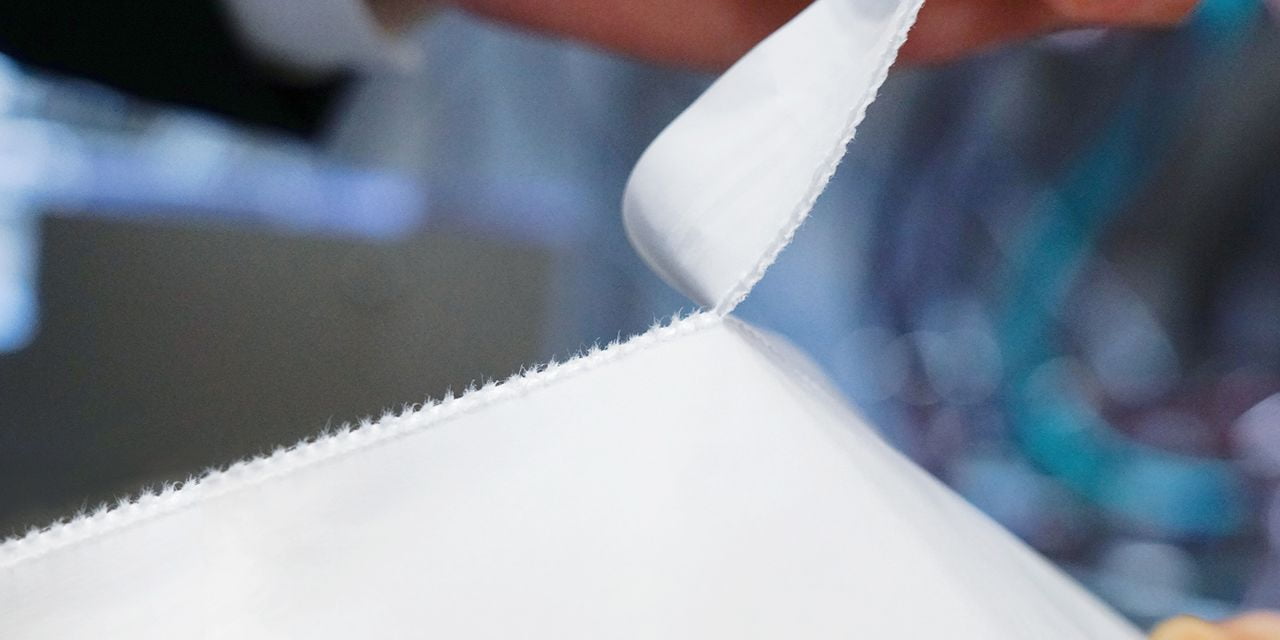

The long-term collaboration between Koehler Paper, part of the Koehler Group, and HDG-Verpackungsmaschinen has resulted in an innovation: For the first time, paper bags can now be produced and filled on horizontal form-fill-seal machines using the “pressure seal module” for the RB-300 HDG packing machine and the specially developed “NexPlus MC” packaging paper from Koehler Paper, which features high mechanical strength and no sealing layer.

Possible formats are 3-edge sealing bags, folding flat-bottom bags (fully sealed) and double bags with a bag length of up to 250 mm and a width of at least 50 mm. The new packaging option can be used for all products that do not require an additional barrier, as well as for secondary packaging of dry products.

Newly developed “pressure seal module”

Consumer demand for greater sustainability in consumer products is unequivocal. According to studies and surveys, the majority of consumers in Europe prefer packaging that contains little to no plastic. Koehler papers are ideally suited for use as packaging: The paper really delivers in terms of the primary purposes of packaging: to protect the contents and their surroundings as well as provide excellent processing properties.

“Sustainable, recyclable packaging solutions made of 100% paper can now be produced using the new pressure seal module for packaging machines and our flexible “NexPlus MC” packaging paper, which does not require a sealing layer,” explains Yevgen Zolotkovski, sales manager for flexible packaging paper at Koehler Paper, when describing the advantages of the new development.

Marcus Behrens, managing director at HDG-Verpackungsmaschinen, adds: “The savings potential is enormous: Material costs drop significantly since no polymer layer is required for sealing, and we have achieved energy savings of 34% during production because hot sealing tools are not needed. In addition, the packaging machine has fewer moving elements and format parts overall. It allows formats to be changed more quickly and results in less wear. The pressure seal module is available for all RB Simplex machines of standard design.

Sustainable innovative paper packaging solutions

With the NexFlex® product range, Koehler Paper has developed a unique and 100 per cent recyclable generation of flexible packaging papers. The aim is to replace plastic in packaging by using so-called barrier paper wherever possible. The range covers a broad spectrum: It includes standard coated and un-coated papers used in laminates for pouches, sachets, and other applications, making them suitable for a wide range of packaging for food and non-food products.

The next generation of papers for flexible packaging is sustainable barrier papers with functional surfaces for product-specific protection (NexPlus®). The NexFlex® product family also includes papers coated on one side with good dimensional stability and high smoothness (NexCoat®), as well as uncoated paper with a natural appearance (NexPure®). Various flexible packaging papers from Koehler Paper were awarded a score of 19 out of a possible 20 points by the environmental service provider Interseroh, along with the ‘Made for Recycling’ seal.

About the Koehler Group

The Koehler Group was founded in 1807 and has been family-run from that moment to the present day. The group’s core business activity lies in developing and producing high-quality specialty paper. It includes — among others — thermal paper, playing card board, drinks coasters, fine paper, carbon-less paper, recycled paper, decor paper, wood pulp board, sublimation papers, and also innovative specialty papers for the packaging industry since 2019.